Views: 0 Author: Amenda Publish Time: 2025-12-04 Origin: FDMAT

For any overseas buyer—whether a brand owner, distributor, or retailer—sourcing custom mouse pads involves navigating three crucial factors: Minimum Order Quantity (MOQ), Lead Time, and Pricing. These three elements are interconnected and ultimately determine the viability and profitability of your project.

This guide provides a transparent, knowledge-based framework to help you understand the industry logic behind these numbers, enabling you to make informed decisions and optimize your supply chain.

The MOQ is not an arbitrary number; it is a necessity driven by production economics. Manufacturers often set higher MOQs for orders with extensive customization options, such as unique designs or branding, because these custom features increase setup and production complexity. Understanding its origin allows you to strategically manage your orders.

MOQs are established to cover the fixed costs associated with starting a production run. These costs include:

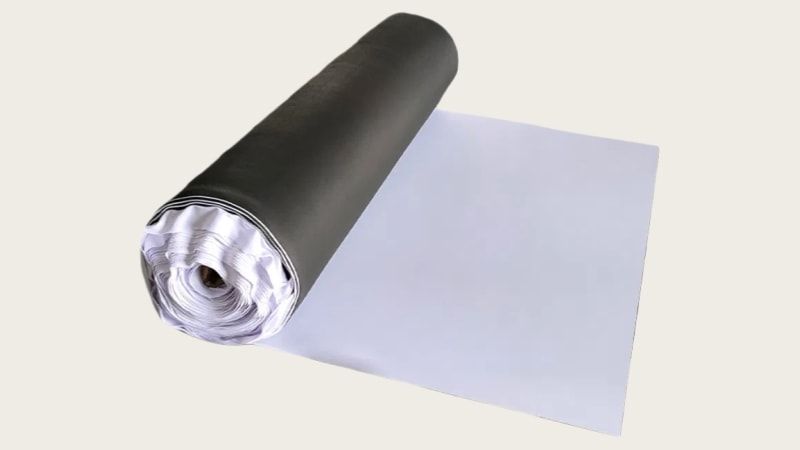

Raw Material Sourcing: Suppliers of fabric and rubber rolls often impose their own large MOQs, which the factory must pass down. Each stage of production, from sourcing to final assembly, requires a minimum quantity to ensure efficiency and quality at every step.

Production Setup: Costs involved in machine calibration, printing plate preparation, mold switching, and initial material testing. At each stage, the manufacturer must allocate resources, making it inefficient and expensive to spread these costs over a small batch.

The required MOQ often varies significantly based on the materials and technology involved:

Factor | Lower MOQ Expectation | Higher MOQ Expectation |

Material | Standard Polyester Fabric, Standard Natural Rubber | PU Leather, Custom-Colored Rubber, Specialized Esports Fabrics |

Printing | Heat Sublimation (less setup time) | Silk Screen Printing (requires complex color separation and plate setup) |

Specifications | Standard sizes ($3mm$) and rectangular cuts | Custom shapes, non-standard thicknesses ($5mm$ or $1.5mm$) |

To negotiate or manage MOQ effectively, focus on reducing the supplier's variable costs:

Simplify Specifications: Stick to standard sizes and thicknesses where possible.

Order Consolidation: Combine multiple designs or SKUs that use the same core material (same fabric type, same rubber base) into one larger production run.

Flexible Packaging: Choose standard packaging (simple OPP bags) over highly customized retail boxes.

Lead time is the total duration from confirmed payment until the goods are ready to leave the factory. Precision in planning is vital for inventory management.

Sampling Lead Time: Typically shorter, but can vary based on whether the sample requires a new print or mold. The sample process includes steps where customers create their design, upload images or artwork, and the final proof must be approved before mass production begins.

Mass Production Lead Time: The bulk of the time is spent here, encompassing material sourcing, printing, processing, and QC.

While printing is a major step, other processes often become bottlenecks:

Material Preparation: Sourcing specialty or custom-colored fabrics.

Machine Scheduling: Factory workload and queue time.

The Locking Edge Process (Stitching): This manual or semi-automated step is labor-intensive and is often the major time bottleneck for large orders.

Additionally, the choice of delivery method and shipping options can also impact the total lead time from factory to destination.

Overseas buyers must plan around peak production periods to avoid critical delays:

Q4 Rush (Sept–Dec): Demand spikes for holiday and Black Friday inventory.

Chinese Lunar New Year (CNY): Factories typically shut down for several weeks, severely disrupting schedules. Plan production 2–3 months ahead of CNY.

Lock in Capacity: For long-term partners, negotiate to have a specific production slot or pre-book core materials ahead of peak season.

Buffer Time: Always build a minimum of 7–10 days of buffer time into your overall project timeline to absorb unexpected delays, including potential delivery delays as well as production issues.

The unit price is determined by layered costs. Focusing solely on the lowest quote often leads to quality sacrifices and hidden fees.

The price is not just based on size, but on quality and complexity:

Material Grade: The purity and density of the natural rubber, and the grade/texture of the fabric surface (e.g., standard Polyester vs. high-grade Esports fabric).

Dimensions & Thickness: Directly proportional to raw material usage.

Post-Processing/Finishing: Stitched edges add significant time and cost compared to simple die-cut edges. The type of stitching (standard vs. hidden/thick) also impacts the price.

Low quotes often omit necessary one-time or situational fees:

Tooling/Mould Fees: For custom shapes or unusual product structures.

Pantone/Color Matching Fees: If extreme color accuracy is required outside of standard CMYK.

Rush Order Fees: To expedite the production line.

FBA/Labeling Services: Costs associated with specialized labeling, bagging, and palletizing required by Amazon FBA.

Cross-Comparison: Get quotes from multiple suppliers, but use the provided material specifications (thickness, fabric type, rubber density) as the baseline for comparison, not just the final number.

Mandatory Testing: The only true validation is through sample testing. A cheap sample that fails quality control is an indicator that the bulk order will be problematic. Providing high-quality samples helps build trust with customers and clients by demonstrating product reliability before bulk orders.

Minimizing risks and ensuring a smooth supply chain requires careful partner selection and internal clarity.

Prioritize OEM/ODM Factories: Opt for an integrated factory that controls the entire process (material processing, printing, stitching, packaging) rather than a pure trading company. This leads to better Quality Control and more reliable Lead Times.

Validate Certifications: Demand proof of compliance with international standards, such as RoHS (Restriction of Hazardous Substances) and REACH, especially if exporting to Europe or North America.

Don’t Settle for Lowest Price: Understand the minimum quality standard your brand requires and adhere to it. Mouse pads intended for extended use or as gifts need higher quality standards and clear specifications to ensure satisfaction.

Be Specific: Never assume details. Clearly define thickness tolerance, color matching standards, and packaging materials in your Purchase Order (PO).

Successful overseas procurement is a balancing act. By understanding the underlying economic logic of MOQ, Lead Time, and Pricing, you shift from reactive buying to strategic sourcing. A reliable supplier is a strategic partner who ultimately saves you money and protects your brand reputation in the long run.

Ready to move forward with clarity and confidence?

Contact us today with your target quantity and specifications. We offer transparent, tiered pricing and provide accurate, realistic lead time estimates based on our end-to-end manufacturing capability, ensuring your next custom mouse pad project is a success.